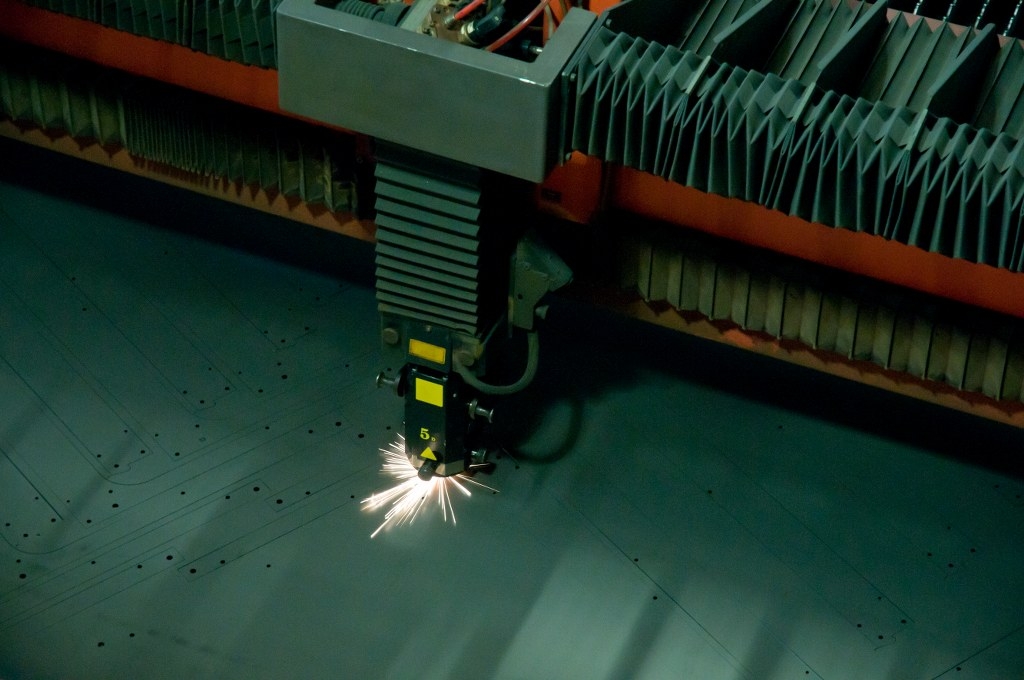

Laser Cutting

Laser is the most versatile and accurate device for sheet metal work.

Laser Cutting

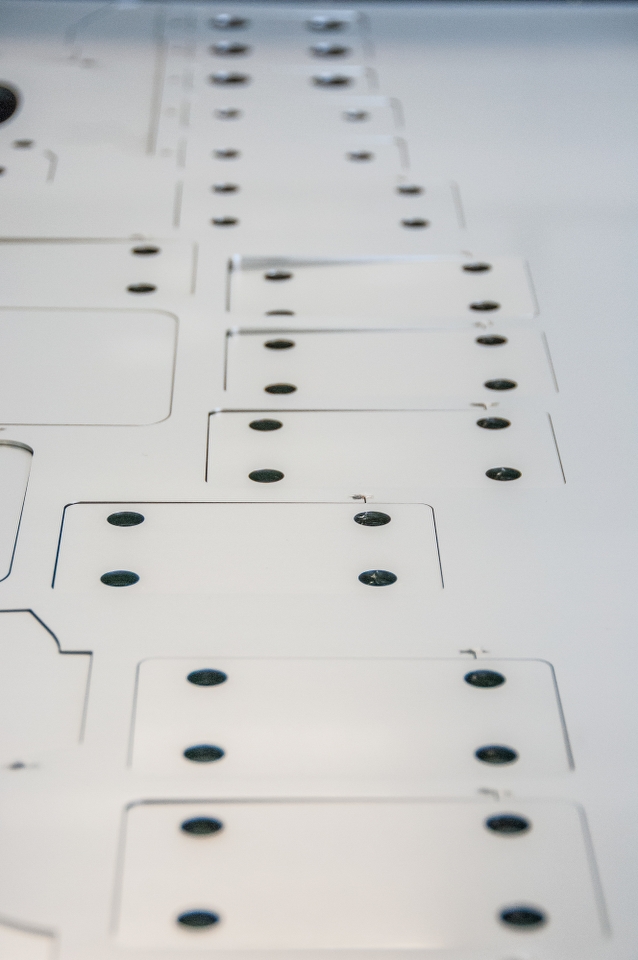

Laser is the most versatile and accurate device for sheet metal work. Available cutting tolerances are of +/- 0,1 mm in wide range of materials like: stainless steel , carbon steel, aluminium . We have four BYSTRONIC and TRUMPF production units for cutting flat sheets (max. power 6 kW).

Maximal material thickness:

- 20 mm (aprox. 0,059056281 in) carbon steel (over 12mm only RAEX LASER or DOMEX)

- 20 mm for stainless steel

- 15 mm for aluminium

- Maximal sheet size: 4000 x 2500 mm

Orders and pricing

If you want to make an order you should give us such information as:

- contact data of the firm which wants to order

- drawing of the cinders in the DXF format (1:1 scale), detailing the thickness of the sheet, the type of material and the dimensional specification of the ordered lot

- the amount of ordered elements

- provenance of materials (delivered by EKO-LASER or separately delivered from outside)

- the preferred time of order completion (minimum 5 business days)

We offer cutting from our material:

- cold rolled sheet metal DC01 – thickness 1-2,5 mm, 2500×1250 mm and 3000×1500 mm format

- hot rolled sheet metal S235JR – thickness 3-15 mm, 3000×1500 mm format

- cold forming of steel sheets DD11 with thicknesses 2–6 mm, Etched / Oiled surface

- hot rolled sheet metal S355J2G3 / S355MC – thickness 3-12 mm, 3000×1500 mm format

- acid-proof and aluminium sheets are ordered at the individual customer’s request

There is a possibility to bring other materials – it depends on the worth of the order.

The quality is treated in our company as a top priority.

The quality is treated in our company as a top priority. The cutting-edge technologies ensure the highest accuracy of performance and give an opportunity to meet customers’ expectations. We give certificates for our materials.